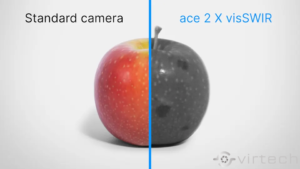

Ensuring the quality of crops such as apples and potatoes is key to meeting market requirements and customer expectations. Traditional inspection methods are mostly based on visual observation, which is time-consuming and not always accurate. Basler’s ace 2 X visSWIR camera, with Basler’s own lighting, lens and software, enables more efficient and reliable inspection in agriculture.

SWIR applications for the analysis of agricultural products

SWIR vision systems can be used in many areas to inspect agricultural crops faster and more reliably, for example to detect damage or contamination.

Product and contaminant separation

Even the smallest differences in the SWIR spectrum are clearly visible, for example, a potato and gravel mixed together can be easily distinguished.

Detecting indentations

SWIR technology can detect even indentations that are barely visible to the naked eye, providing more reliable quality control.

Estimation of sugar content

The sugar content of fruits, and therefore the degree of ripeness and harvesting time, can be determined using SWIR imaging.

Why should you use SWIR in food control?

The unique properties of short-wave infrared light open up new possibilities for quality control by detecting variations below the surface. Traditional visual inspection methods are often time-consuming, subjective and prone to error. Images in the visible spectrum do not always provide sufficient detail to detect quality deviations. SWIR technology, on the other hand, is able to “see through” the surface, so that previously hidden defects can be detected.

Suppression on an apple compared at 1000 nm (NIR) and 1350 nm (SWIR).

SWIR imaging requires special equipment

Because shortwave infrared light has different properties, choosing the right lenses, filters and lighting is key to achieving excellent image quality.

Components of the Basler SWIR vision system

Components of the Basler SWIR vision system

1. SWIR lighting – Provides stable and uniform lighting conditions.

2. SWIR lighting control – Optimisation of lighting.

3. Optical filters for SWIR applications – For wavelength-specific imaging.

4. Basler ace 2 X visSWIR camera – For visible and shortwave infrared light detection.

5. SWIR lenses – Specially designed lenses for precise imaging.

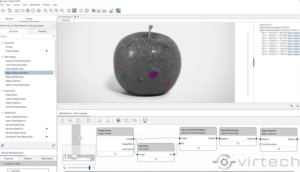

Intelligent software solutions: blob analysis

The effectiveness of vision systems is determined not only by the hardware, but also by the software. The Blob Analysis module in the Basler pylon software package allows automatic detection and analysis of darker areas, so that defects, contamination or sugar content discrepancies can be accurately identified.

Why is blob analysis important?

It distinguishes between the product and the defective parts.

Automate the detection of defective products.

Improves control efficiency.

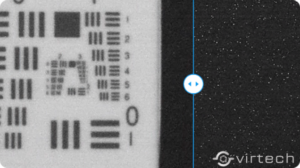

Automatic pixel error correction for even better image quality

The Basler ace 2 X visSWIR cameras use Sony’s SenSWIR sensors, which have smaller pixels and therefore provide higher resolution than conventional sensors.

Pixel Correction Beyond: Images without pixel errors

Pixel errors, common in SWIR sensors, can negatively affect image processing. Basler’s Pixel Correction Beyond algorithm identifies and corrects these errors in real time without distorting the image information.

The benefits of SWIR technology in agricultural monitoring

Complete vision system with coordinated components – For optimum image quality and accurate defect detection.

Reliable defect detection with advanced algorithms – Small defects and deviations can be detected, reducing the risk of human error.

More efficient sorting process – Optimised product processing based on real-time analysis.