Typical Application Areas and Cameras

Welded seams, clearance, and quality control, assembly activities, and identification as well as orientation are some of the areas where cameras are used in control technology, robot control, and placement (Robot Guidance).

Basler ace 2: Designed to meet a variety of optical requirements

- The next generation of ace: Modern CMOS sensors, enhanced hardware architecture, and better image quality

- Two product lines, each adapted to a certain optical requirement – ace 2 Pro and ace 2 Basic

- ace 2 Basic: renowned Basler reliability combined with a comprehensive computer vision feature set for common machine vision applications.

- For optimal performance, ace 2 Pro has unique features like as Pixel Beyond, Compression Beyond, and PGI.

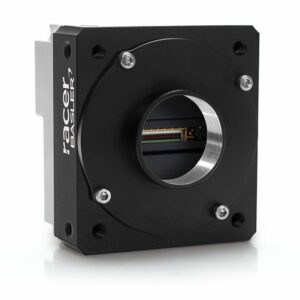

Basler ace: Particularly compact, low-cost, and high-performance

- For maximum precision, the I/O connector reduces latency and jitter times.

- Firmware with a lot of functionality for smart applications

- Flexible cabling thanks to GigE’s 100-meter cable length

Basler beat: brilliant CMOS image quality and a proven design

- 12 MP sensor with high resolution

- Over 62 fps

- Housing that is both compact and sturdy for easy integration

- Price/performance ratio is quite appealing.

- Camera Link connections with high bandwidth for maximum image capture speed

Basler blaze: High precision for cost-effective real-time 3D imaging

- The latest Sony DepthSenseTM IMX556PLR sensor technology provides outstanding 3D imagery.

- The time-of-flight approach allows for precise, practically millimeter-accurate optical measurements.

- Large measuring range, equivalent to two Euro pallets or a small automobile.

- Pre-processed 3D point clouds and 2D intensity images are streamed in real time.

- Daylight capabilities and IP67 protection ensure consistent results under challenging settings.

- Independent of light and contrast

- Compact architecture and Gigabit Ethernet make system integration simple.

- Sample programs and a user-friendly and platform-independent programming interface

- Without mutual interference, reliable functioning in multi-camera systems

Basler boost: CXP-12 for high frame rates & resolutions

- High-performance CoaXPress 2.0 interface and the latest CMOS sensor technology

- Extremely large bandwidth: It is now one of the fastest interfaces on the market, with up to 12.5 Gbps per cable.

- Synchronization accuracy: Even with multi-camera systems with very short latency times, precise camera synchronization is possible.

Basler dart: small, flexible USB3 Vision standard-compliant device.

- Starting at 99 euros, the price/performance ratio is outstanding.

- A global shutter sensor is used to better identify moving images.

- Extremely low power consumption and heat production

Code Recognition

The recognition of a broad variety of forms of codes, such as data matrix codes, but also color codes and plain text (OCR/OCV optical character recognition or verification), especially on metal surfaces, is one of the applications of cameras with code identification.

Basler ace 2: Designed to meet a variety of optical requirements

- The next generation of ace: Modern CMOS sensors, enhanced hardware architecture, and better image quality

- Two product lines, each adapted to a certain optical requirement – ace 2 Pro and ace 2 Basic

- ace 2 Basic: renowned Basler reliability combined with a comprehensive computer vision feature set for common machine vision applications.

- For optimal performance, ace 2 Pro has unique features like as Pixel Beyond, Compression Beyond, and PGI.

Basler ace: Particularly compact, low-cost, and high-performance

- For maximum precision, the I/O connector reduces latency and jitter times.

- Firmware with a lot of functionality for smart applications

- Flexible cabling thanks to GigE’s 100-meter cable length

Basler beat: brilliant CMOS image quality and a proven design

- 12 MP sensor with high resolution

- Over 62 fps

- Housing that is both compact and sturdy for easy integration

- Price/performance ratio is quite appealing.

- Camera Link connections with high bandwidth for maximum image capture speed

Basler blaze: High precision for cost-effective real-time 3D imaging

- The latest Sony DepthSenseTM IMX556PLR sensor technology provides outstanding 3D imagery.

- The time-of-flight approach allows for precise, practically millimeter-accurate optical measurements.

- Large measuring range, equivalent to two Euro pallets or a small automobile.

- Pre-processed 3D point clouds and 2D intensity images are streamed in real time.

- Daylight capabilities and IP67 protection ensure consistent results under challenging settings.

- Independent of light and contrast

- Compact architecture and Gigabit Ethernet make system integration simple.

- Sample programs and a user-friendly and platform-independent programming interface

- Without mutual interference, reliable functioning in multi-camera systems

Basler boost: CXP-12 for high frame rates & resolutions

- High-performance CoaXPress 2.0 interface and the latest CMOS sensor technology

- Extremely large bandwidth: It is now one of the fastest interfaces on the market, with up to 12.5 Gbps per cable.

- Synchronization accuracy: Even with multi-camera systems with very short latency times, precise camera synchronization is possible.

Basler dart: small, flexible USB3 Vision standard-compliant device.

- Starting at 99 euros, the price/performance ratio is outstanding.

- A global shutter sensor is used to better identify moving images.

- Extremely low power consumption and heat production

We give robots the capability to see.

Robots are already executing tasks that are difficult, impossible, or exceedingly tedious for people in numerous industries today. They are generally faster than people and provide constant quality and reliability. However, because a robot can only do a certain task in a limited range of motion, the areas of applicability are constrained. Computer vision can help robots become “smarter” and expand their applications. Basler has extensive experience in the field of computer vision. We give robots the ability to see.

Detection and localisation of objects

Robotic applications that are guided by a vision system do not require precise object location. If an object is within the given working space, the robot can identify, localize, and pick it.

Object identification and sorting

Guidance by a vision system enables the robotic application to sort based on object identification. Each object can trigger an individual action, e.g. sorting into different categories.

Explore New Possibilities Thanks to Vision-guided Robotics

Robots with the ability to see can execute jobs that would otherwise take a lot of time, effort, and money.

Vision-guided robotics can be used in a variety of applications.

Transport and Material Handling

Pick-and-place, labeling, palletizing, packaging, and material transfer are all possible with vision-guided robotics. Increased flexibility, improved staff collaboration, and dependable operation are just a few of the potential advantages. obotics.

Quality Assurance and Process Control

All of these applications, including part inspection, metrology, classification, assembly, and machine tending, require imaging for a robust and safe implementation. Higher accuracy, throughput, and downtime can all be achieved with the correct robotic vision system.

For vision Experts

For robot applications, vision technology is becoming increasingly important. You, as a vision expert, are undoubtedly well aware of this. We teach you how to successfully mix both technologies in this article.

Extensice Portfolio

- VGA to 24 MP resolution cameras are available.

- Cameras with a global shutter are best for applications involving moving objects, while cameras with a rolling shutter are better for budget-conscious applications.

- 3D imaging with Time-of-Flight cameras is precise and cost-effective.

- Compatible components include lenses and illumination that are appropriate for the purpose, as well as drag chain cables.

Robotics-Compilant Interface

- USB 3.0 standard interface with high throughput

- If the camera is situated outside the arm (off-arm), slightly offset or further distant, use the GigE interface.

- All common industrial PCs and embedded systems, as well as many robot controllers, support both interfaces.

Set up Your Vision System

- ROS compatibility: The Robot Operating System (ROS) assures that all components are compatible, which includes our cameras.

- Drag&bot as a manufacturer-agnostic middleware – when used in conjunction with the drag&bot software, integrating vision into your robot application is a breeze.

- Integration with a wide range of well-known and current robotic systems (Epson, ABB, TM)